Battery Leak Tester

Overview

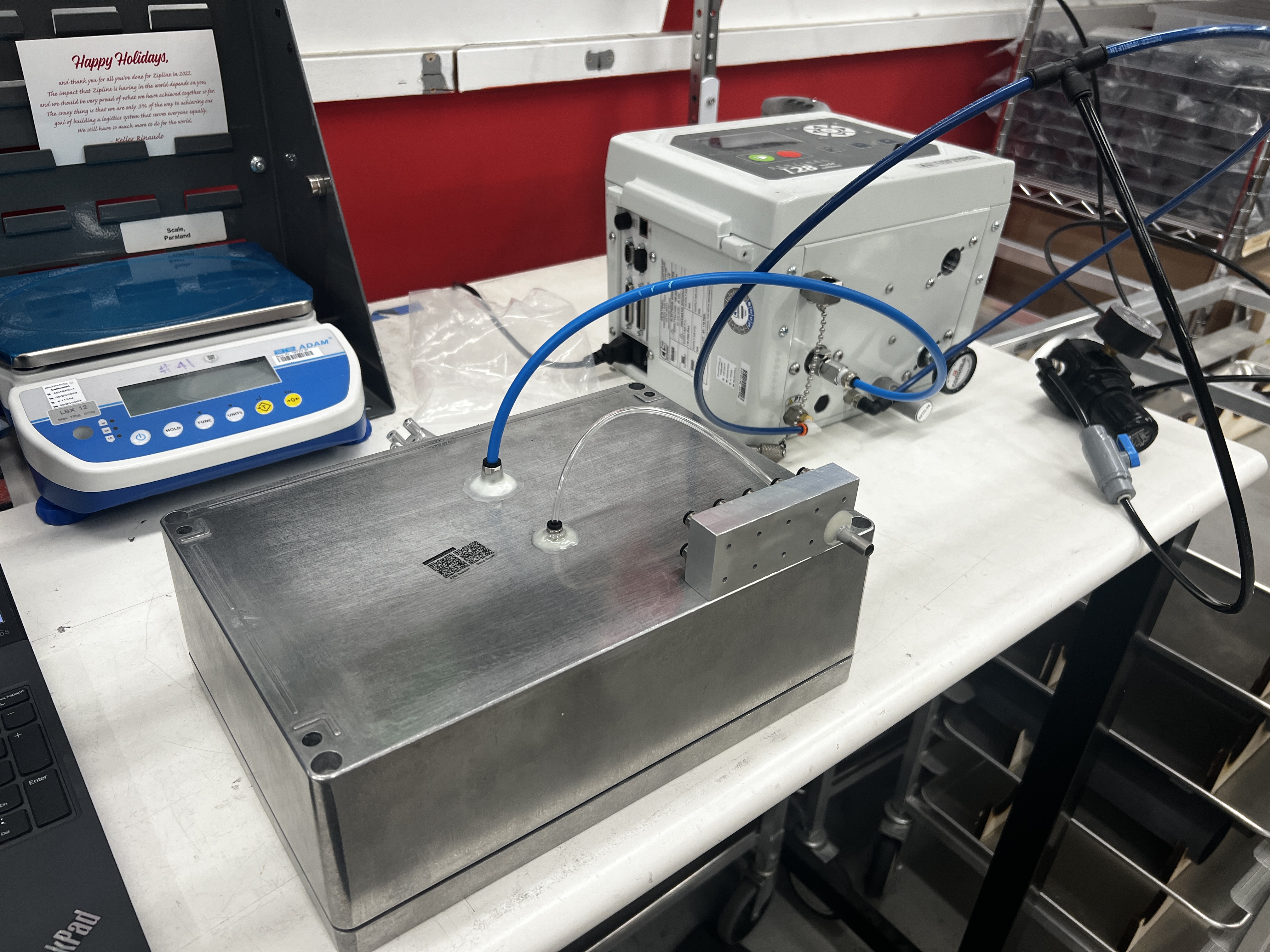

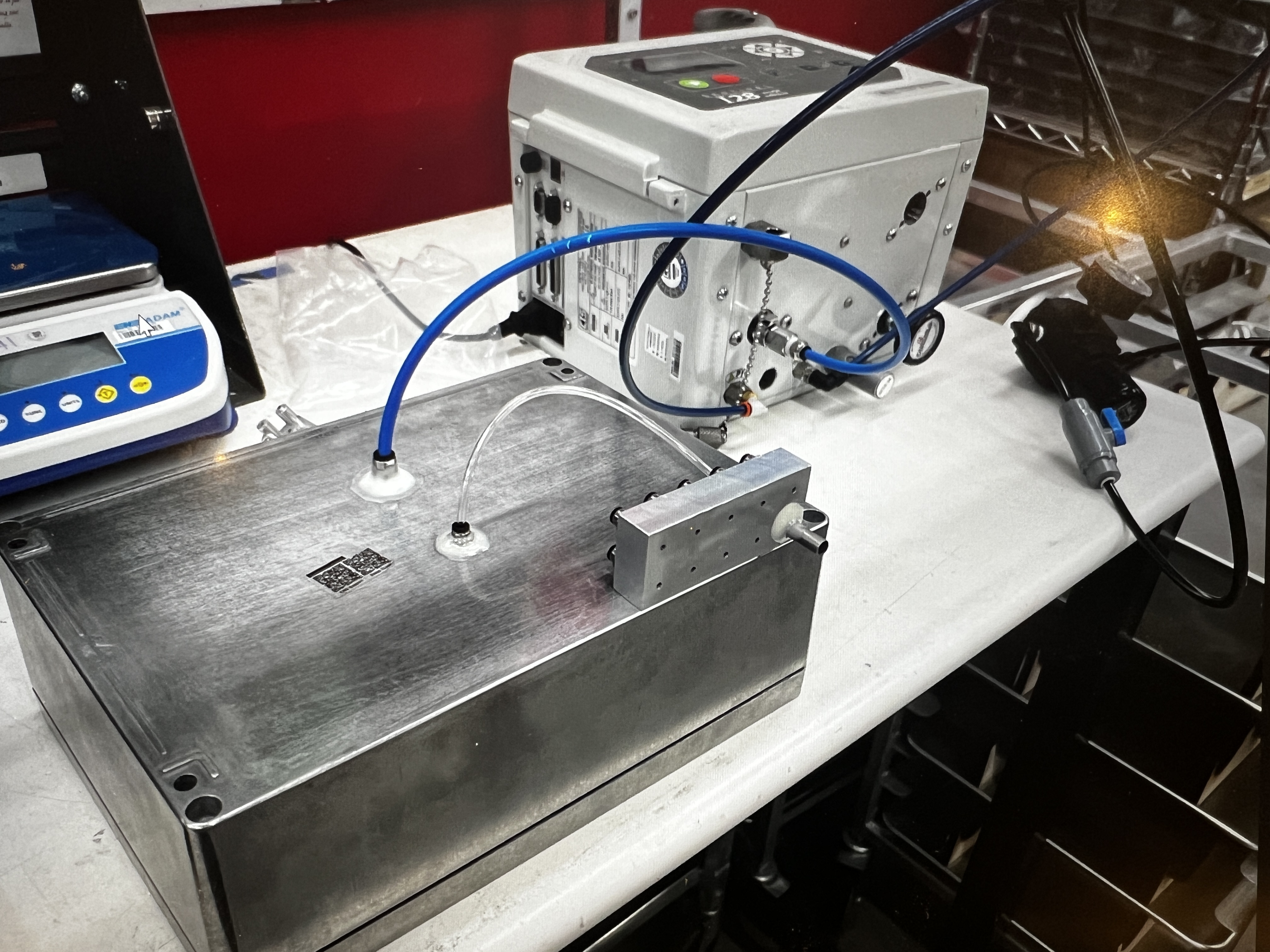

Ensuring IPX5-rated battery packs without destruction. I developed a non-destructive leak test for a drone delivery startup, replacing water-based testing with air pressurization. A correlation study linked air leak rate to water ingress, enabling faster, automated detection. The system achieved >99% accuracy in identifying manufacturing defects while cutting test cycle time to 1 minute per pack.

Technical Details

- Testing Requirement: IPX5 water resistance for battery packs

- Testing Method: Non-destructive air pressurization

- Correlation Study: Air leak rate mapped to water ingress

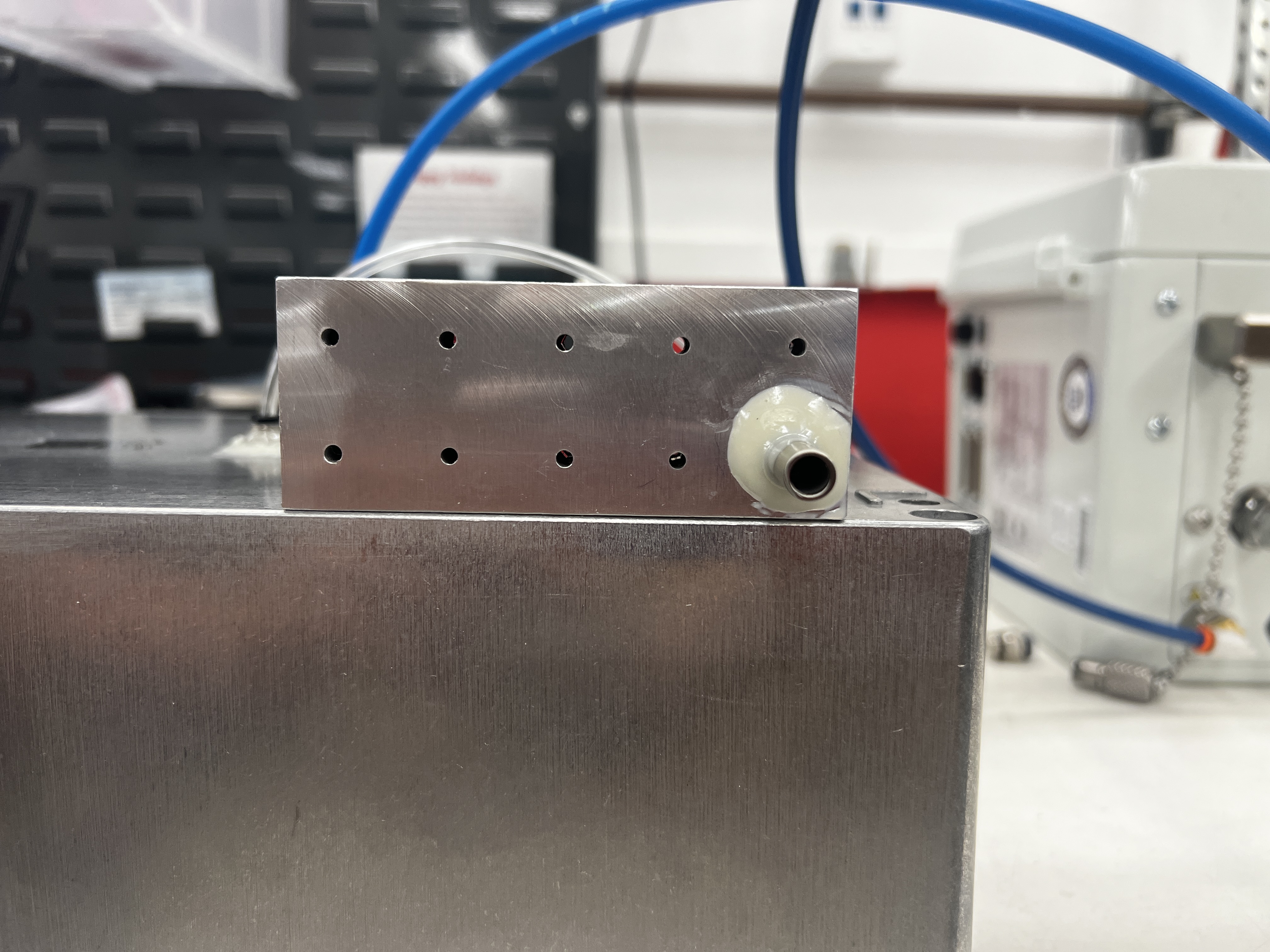

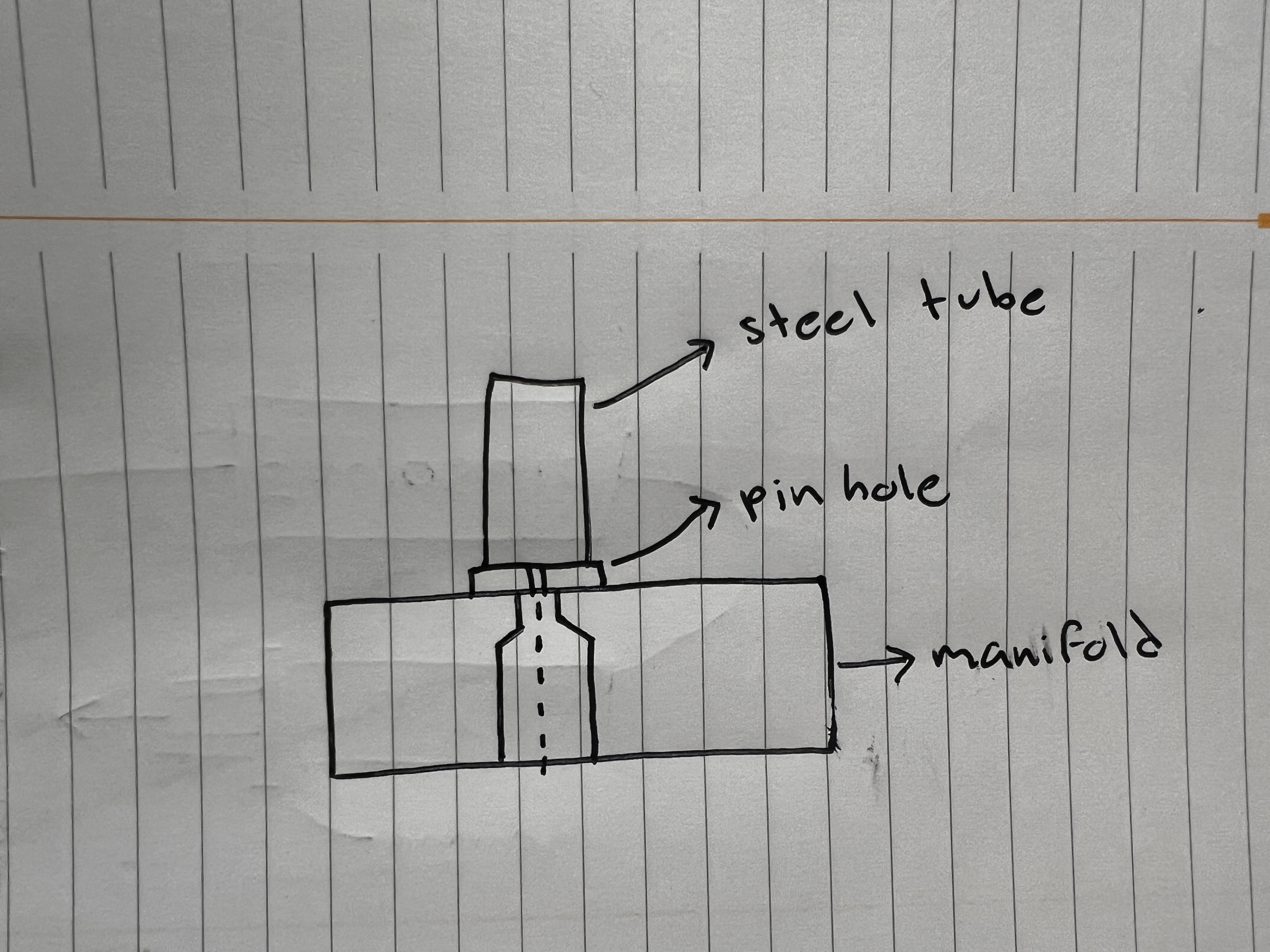

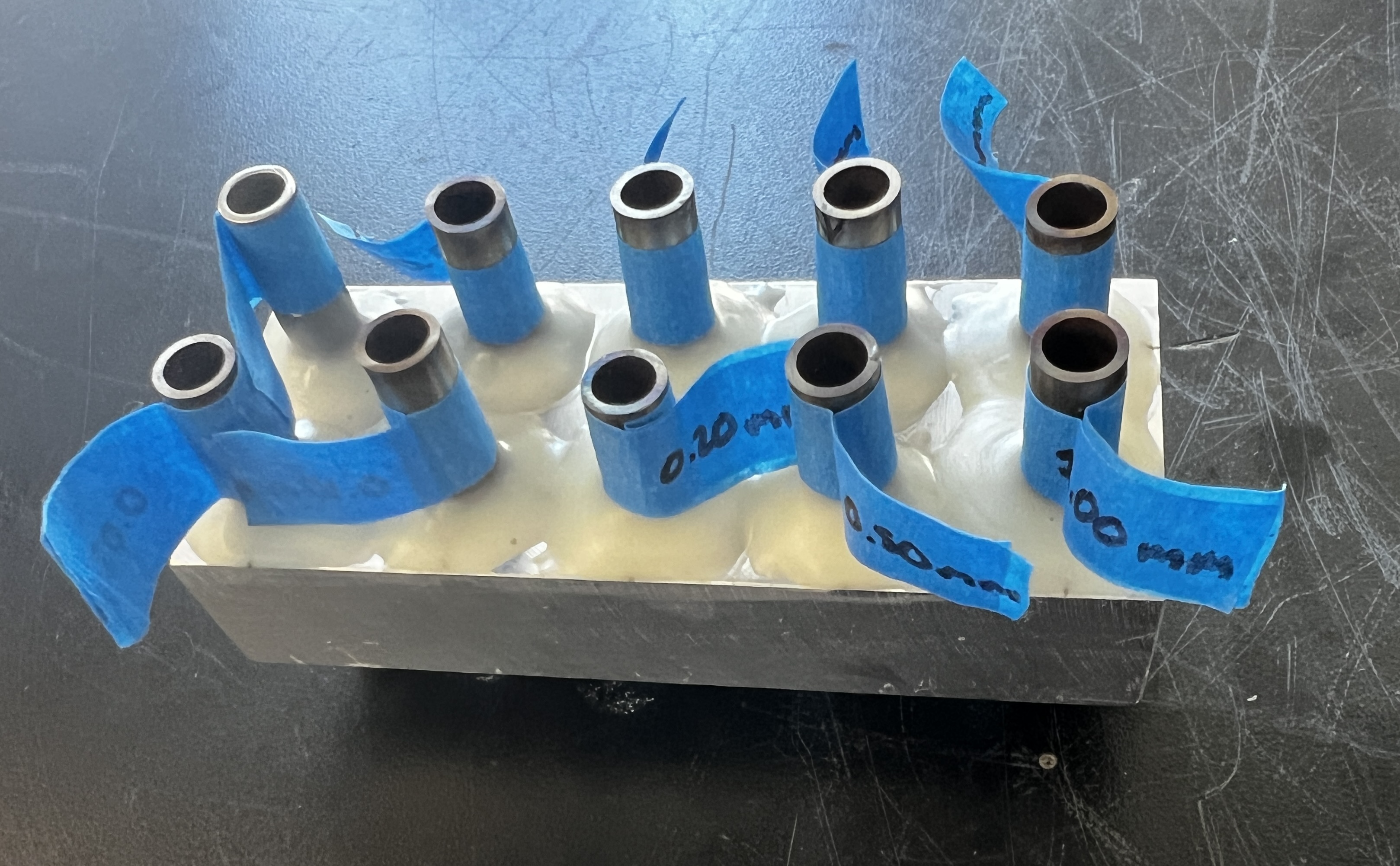

- Leak Characterization: Custom manifold with optical laser pinholes

- Cycle Time: 1 min per pack

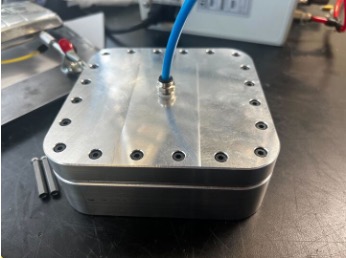

- Calibration: Machined aluminum master volume for test equipment

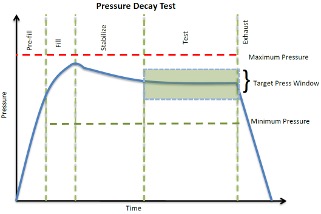

- Test Methods: Pressure decay, wind-blown rain testing

- Automation: MATLAB-based EOL test app

- Detection Accuracy: >99% in identifying manufacturing errors

- Pass/Fail Criteria: Defined acceptable water ingress levels

Development Process

- Correlation Study: Established air-to-water leak rate relationship using precision optical laser pinholes.

- Calibration: Designed and machined an aluminum master volume to validate equipment accuracy.

- Test Execution: Conducted pressure decay and wind-blown rain tests.

- Automation: Developed a MATLAB-based test app for fully automated EOL testing.

- Quality Control: Defined strict pass/fail criteria based on water ingress thresholds.

Results

- Faster Testing - Reduced test cycle time to 1 min per pack.

- Non-Destructive - Eliminated the need for destructive water testing.

- High Accuracy - Achieved >99% defect detection rate.

- Scalable & Repeatable - Standardized testing for consistent quality control.