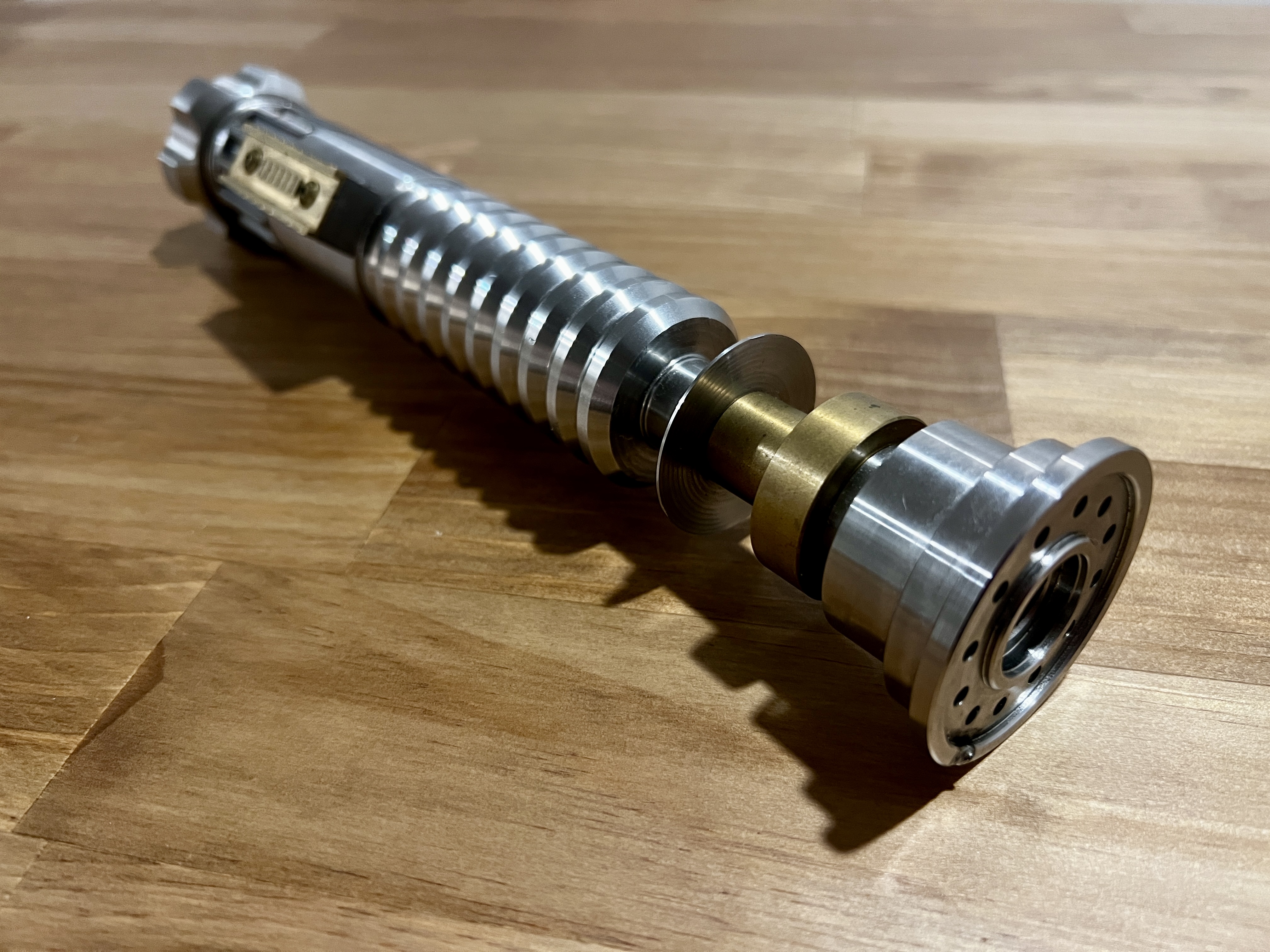

Lightsaber Hilt

Overview

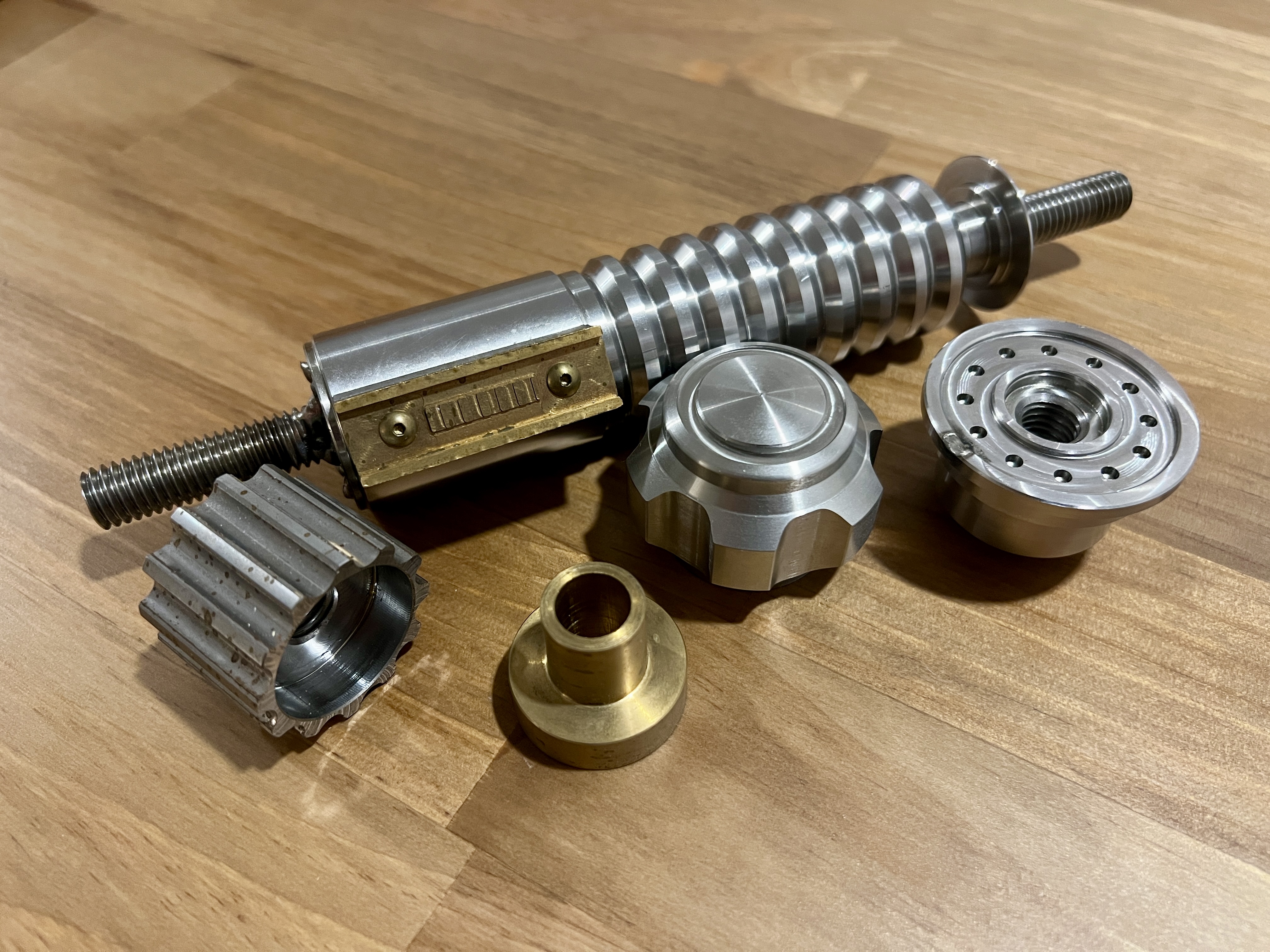

A passion project turned machining masterclass. I designed and machined a 7-piece lightsaber hilt from brass, stainless steel (SS316), and mild steel to sharpen my CNC lathe and mill skills. The project tested my problem-solving—leading to welding, heat treating, and material upgrades. After 50 hours of design, planning, and machining, it is now my living room's centerpiece.

Technical Details

- Components: 7 machined parts (brass, SS316, mild steel)

- Software: CAD and CAM in Fusion 360

- Machining Process: CNC lathe & CNC mill

- Heat Treatment: Self-taught heat treating process for durability

- Scrap Rate: 2 failed hilts before a final successful build

- Time Investment: 50+ hours

Development Process

- Design & Programming: Modeled in Fusion 360, generated toolpaths for CNC machining.

- Machining & Challenges: Cut and shaped components on CNC lathe and mill.

- Material Issue: Discovered galvanic corrosion on mild steel due to dissimilar metal contact.

- Solution: Upgraded all mild steel components to SS316 to eliminate corrosion.

- Learning & Repairs: Heat treated parts in my garage and welded a threaded rod after a tap broke.

Results

- Functional & Durable - Eliminated corrosion issues with full SS316 construction.

- Hands-On Learning - Improved machining, heat treating, and welding skills.

- Personal Achievement - A handcrafted centerpiece in my home decor.