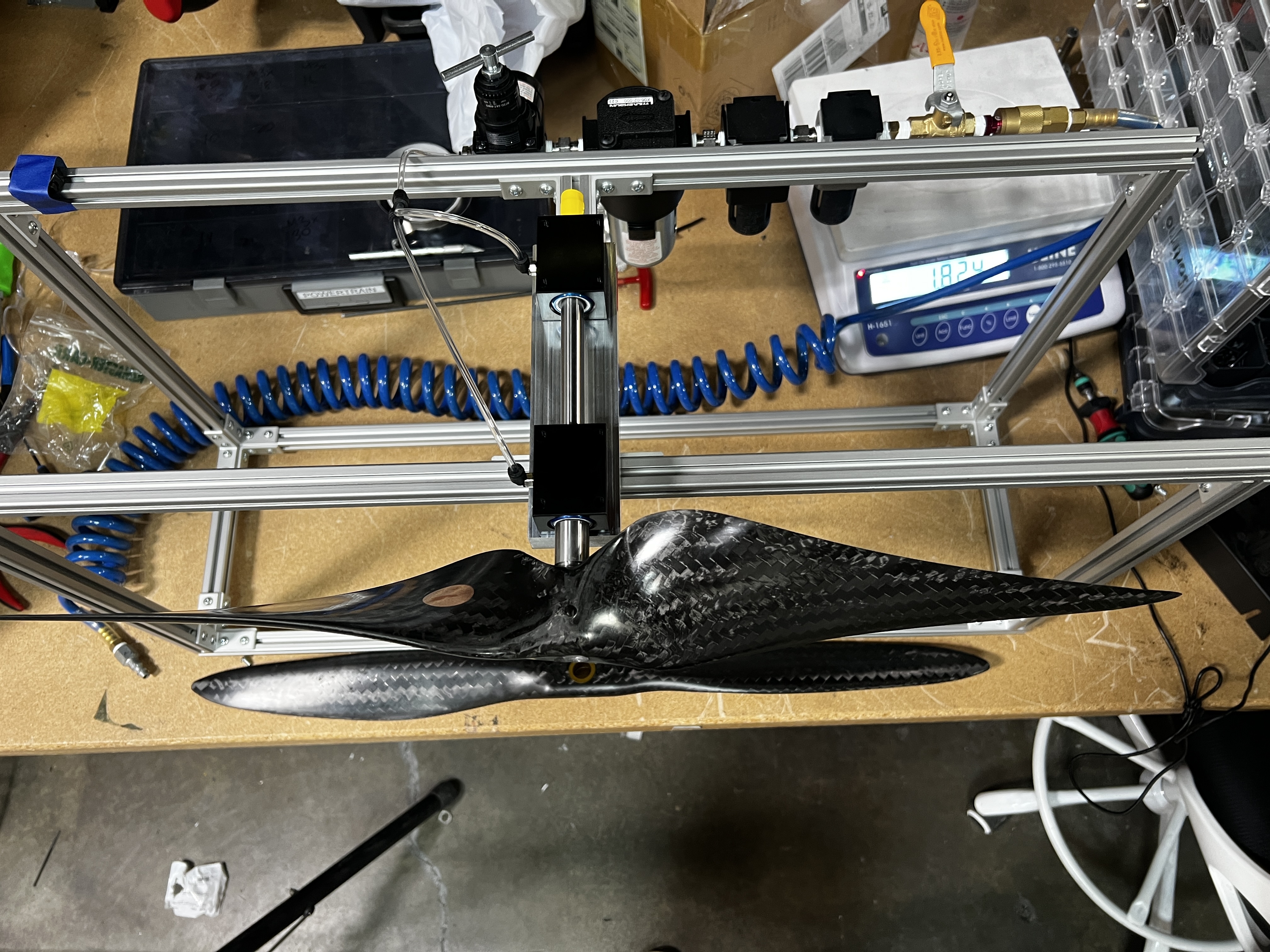

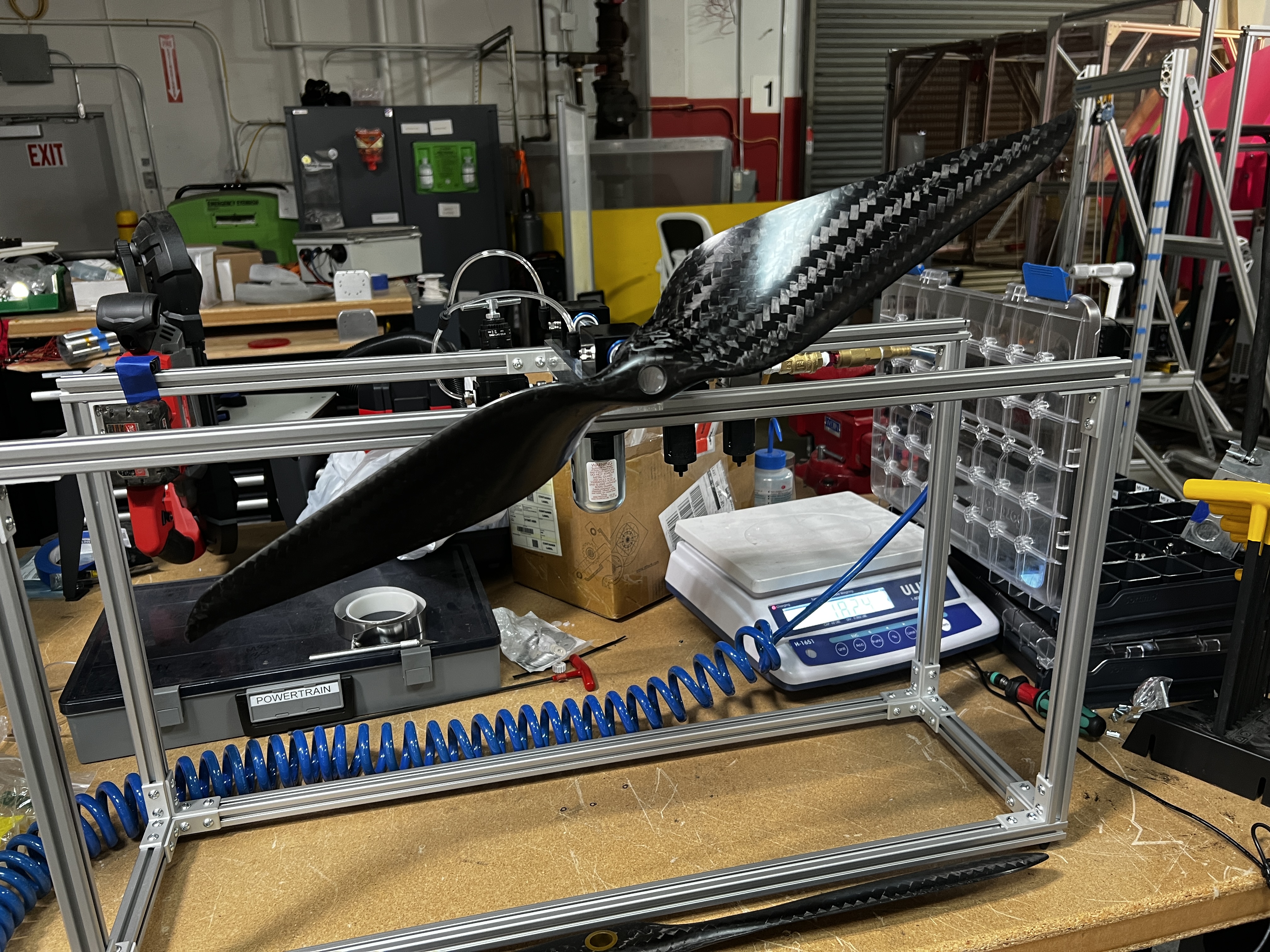

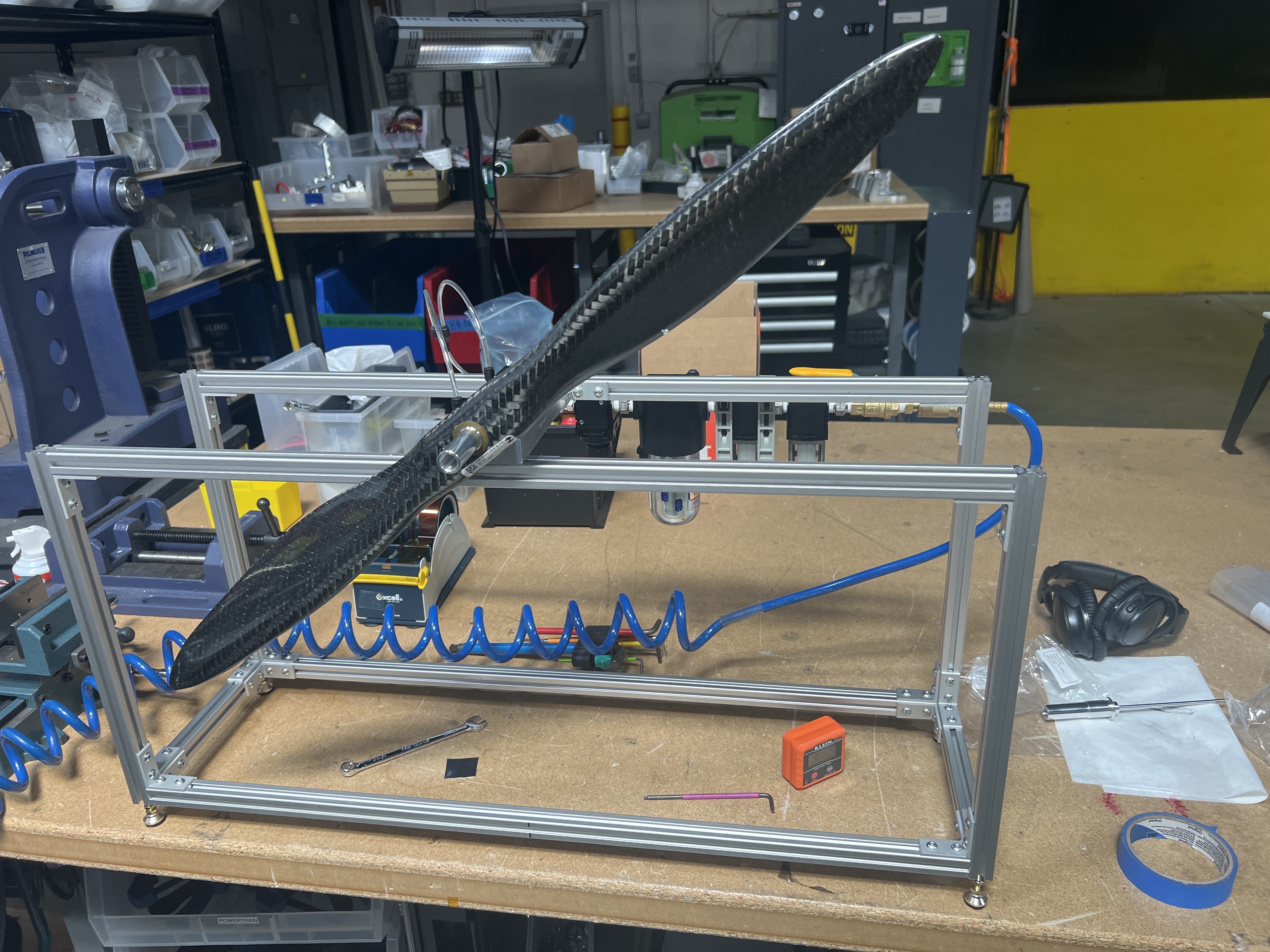

Propeller Static Balancer

Overview

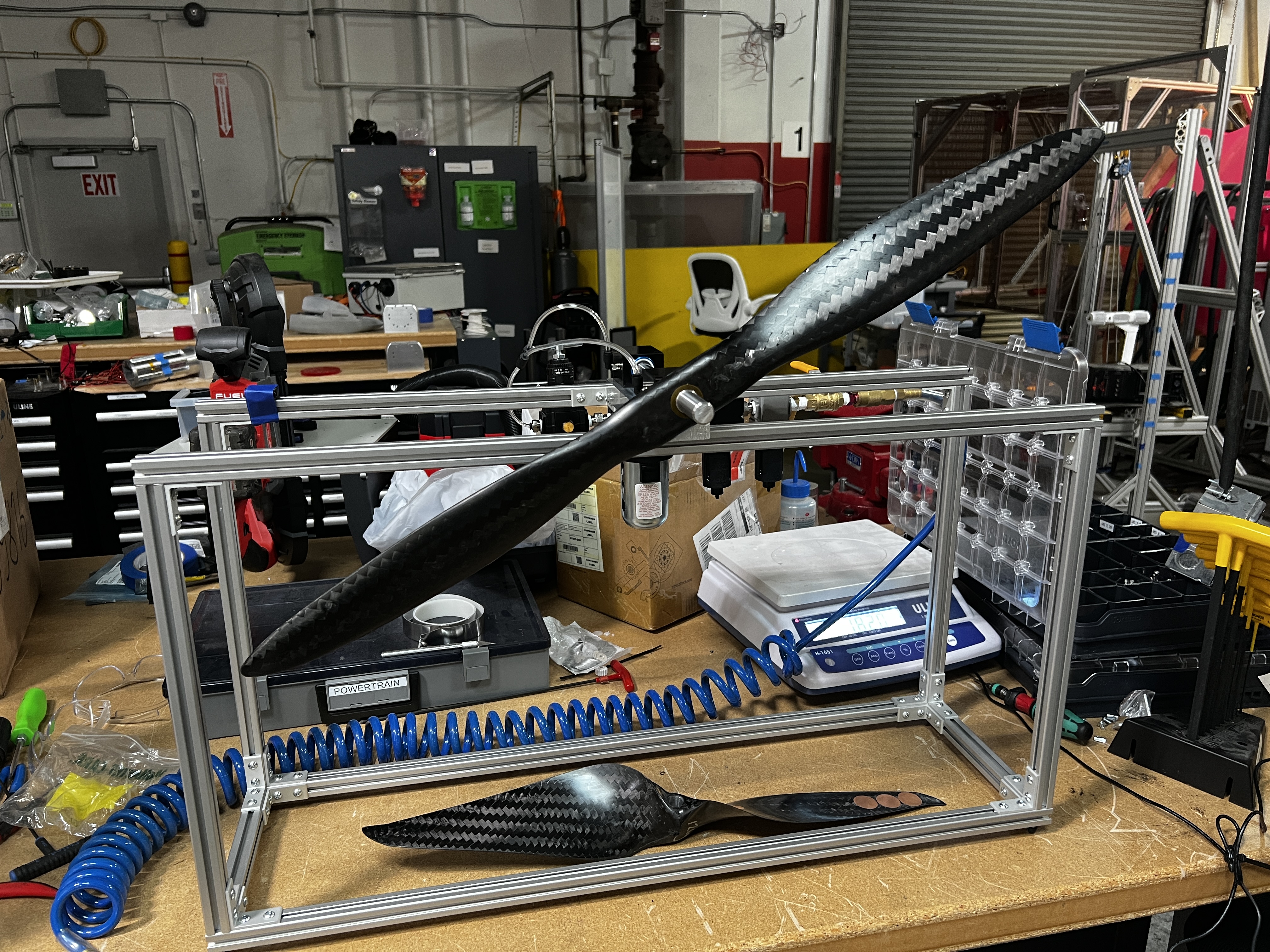

Precision matters in drone delivery. I developed an end-of-line static balancer to fine-tune quadcopter propellers, reducing vibrations and improving flight stability. The system minimizes friction using air bearings, allowing even the smallest imbalance to be detected. This upgrade cut balancing time from 5 minutes to under 30 seconds per prop—a 10x improvement.

Technical Details

- Purpose: EOL static balancer for quadcopter propellers

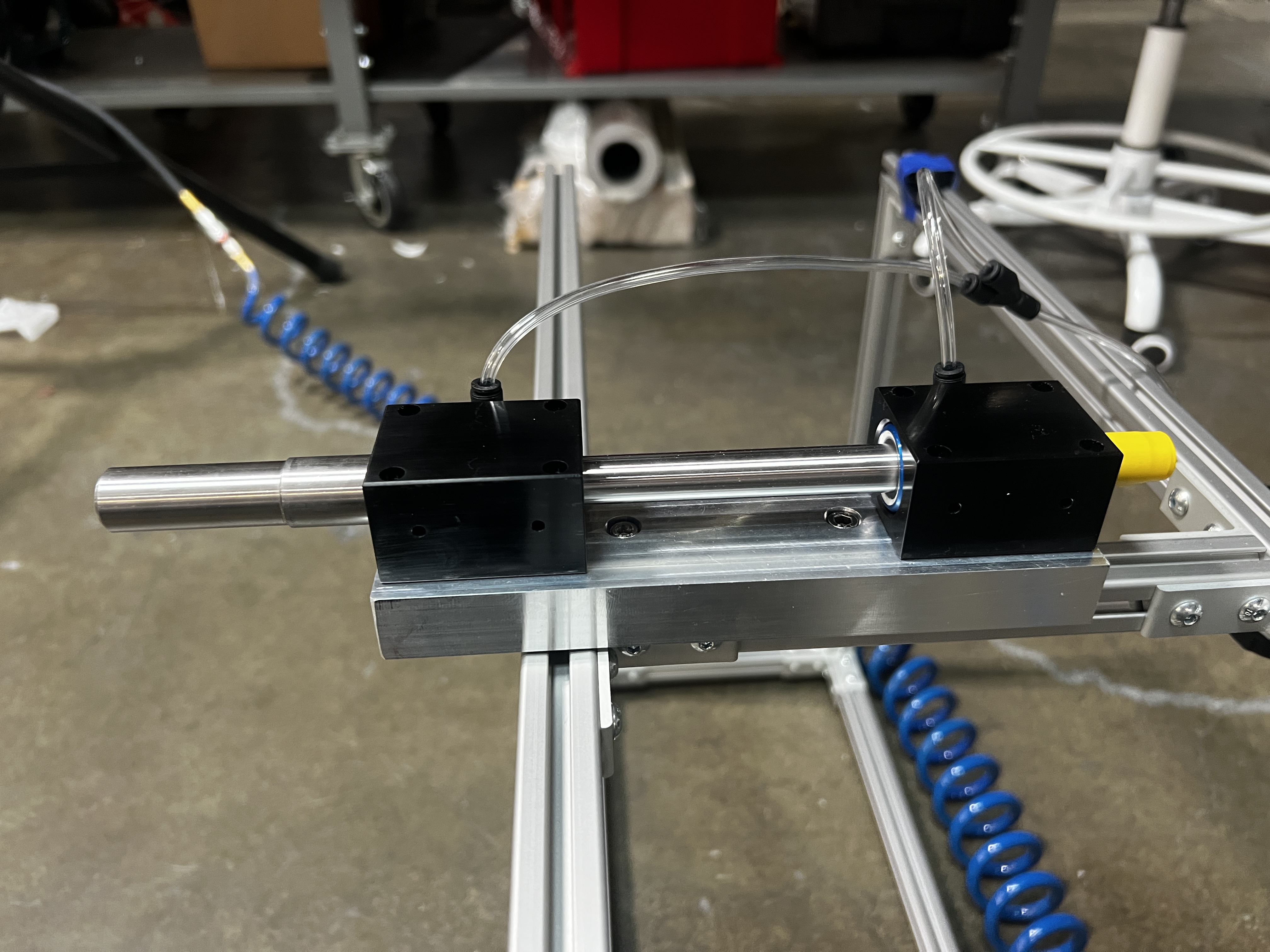

- Friction Reduction: Air bearings for ultra-low resistance

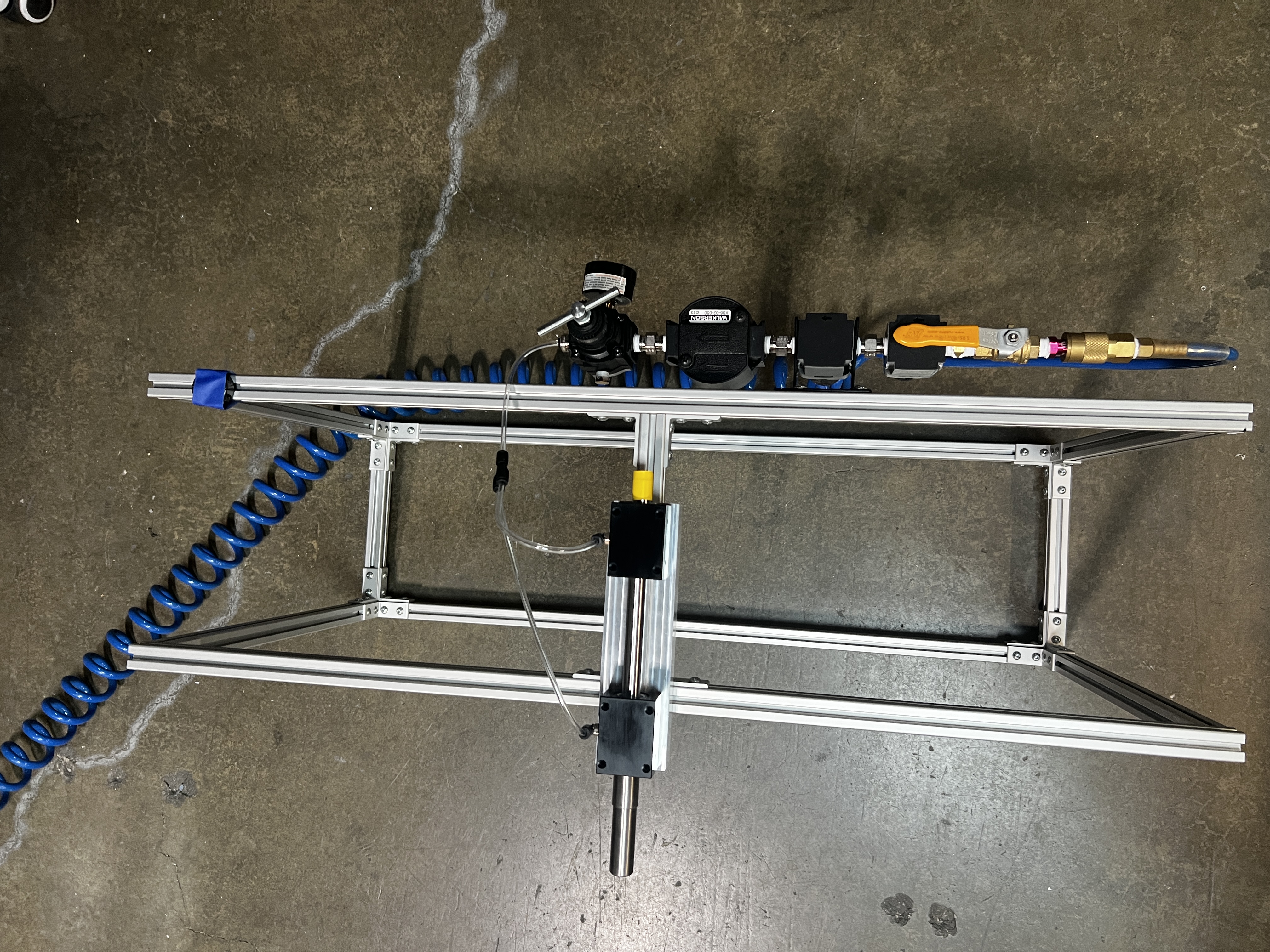

- Power System: Pneumatically powered

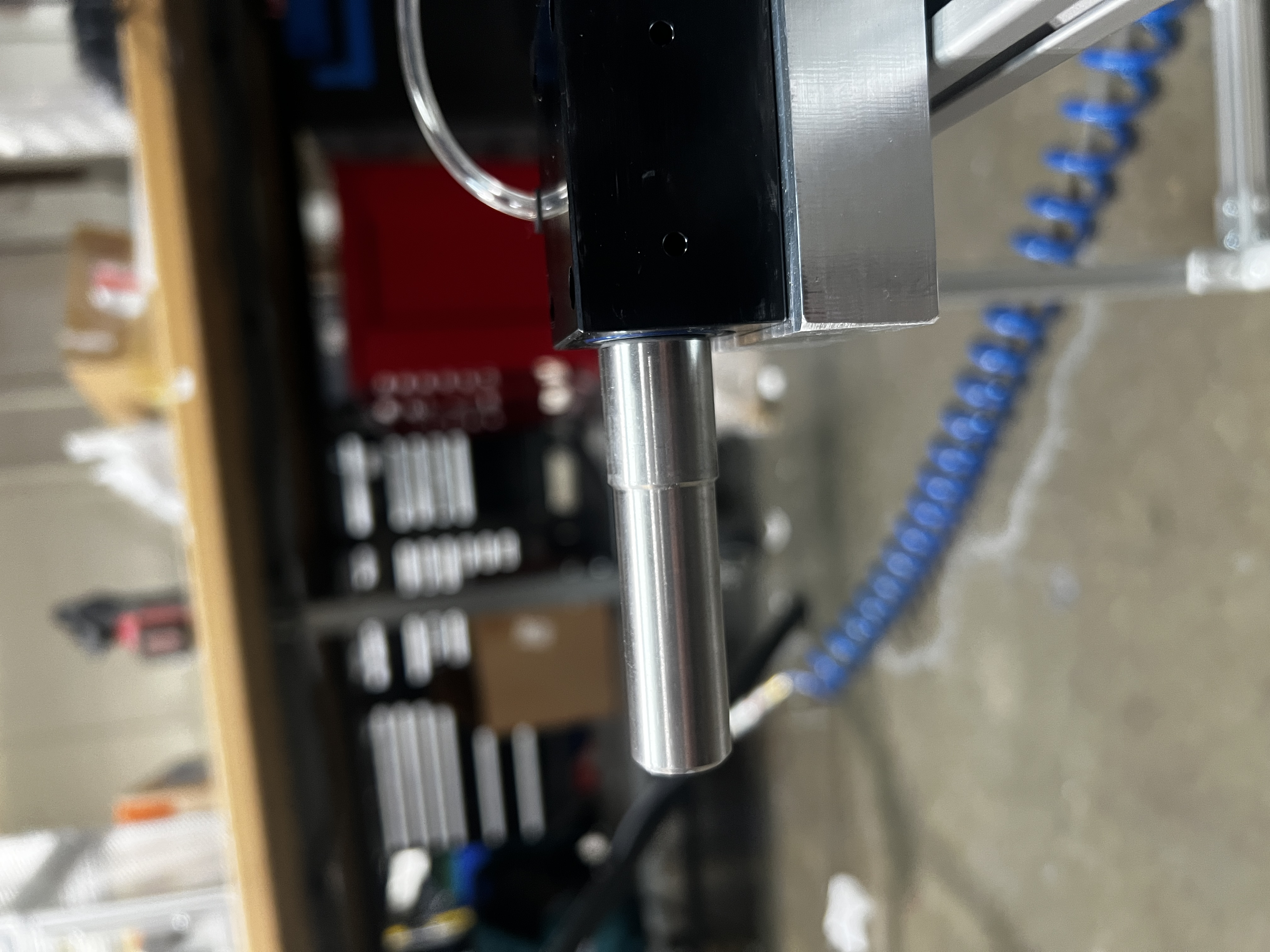

- Frame & Structure: Machined aluminum brackets, hardened SS316 shaft, aluminum extrusion frame

- Precision Design: Tight tolerances to maintain shaft straightness

- Moment of Inertia: Minimized to enhance imbalance detection

- Cycle Time: <30s per prop (previously 5 min)

- Balancing Aid: Laser pointer for counterweight positioning

- Pass/Fail Criteria: Defined limits for acceptable imbalance

Development Process

- Balancing Principle: Explained the importance of propeller balance in reducing drone vibration and improving efficiency.

- Friction Reduction: Integrated air bearings to maximize sensitivity to imbalance.

- Structural Precision: Designed aluminum brackets and a hardened steel shaft to achieve tight tolerances.

- Automation & Speed: Reduced balancing time from 5 min to under 30s with improved workflow.

- Laser Alignment: Used a laser pointer to pinpoint the optimal counterweight position.

Results

- 10x Faster - Cut balancing time from 5 minutes to under 30 seconds.

- Enhanced Precision - Air bearings and low moment of inertia improved imbalance detection.

- Repeatable & Reliable - Standardized pass/fail criteria for consistent results.