Competition RC Aircraft

Overview

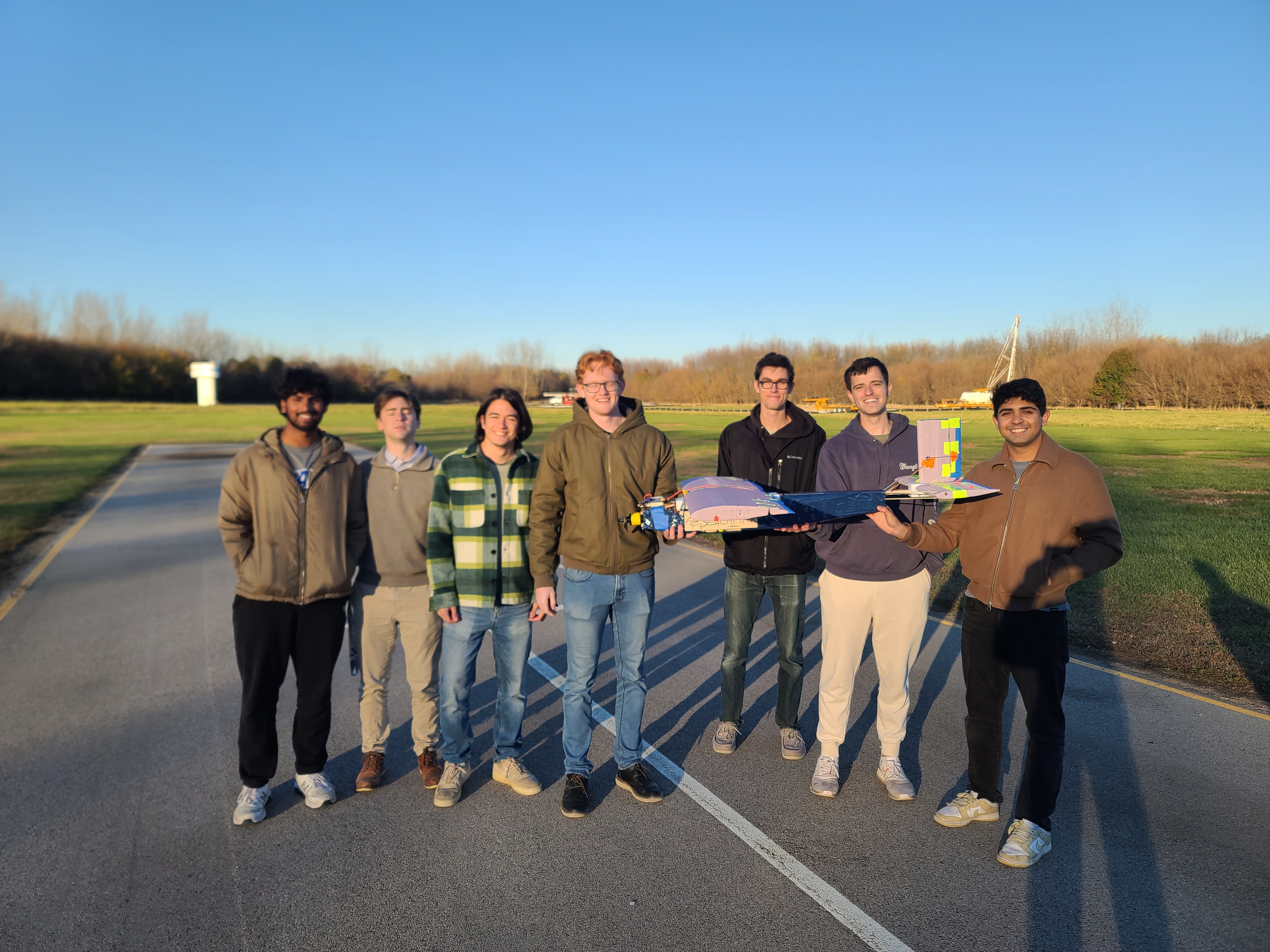

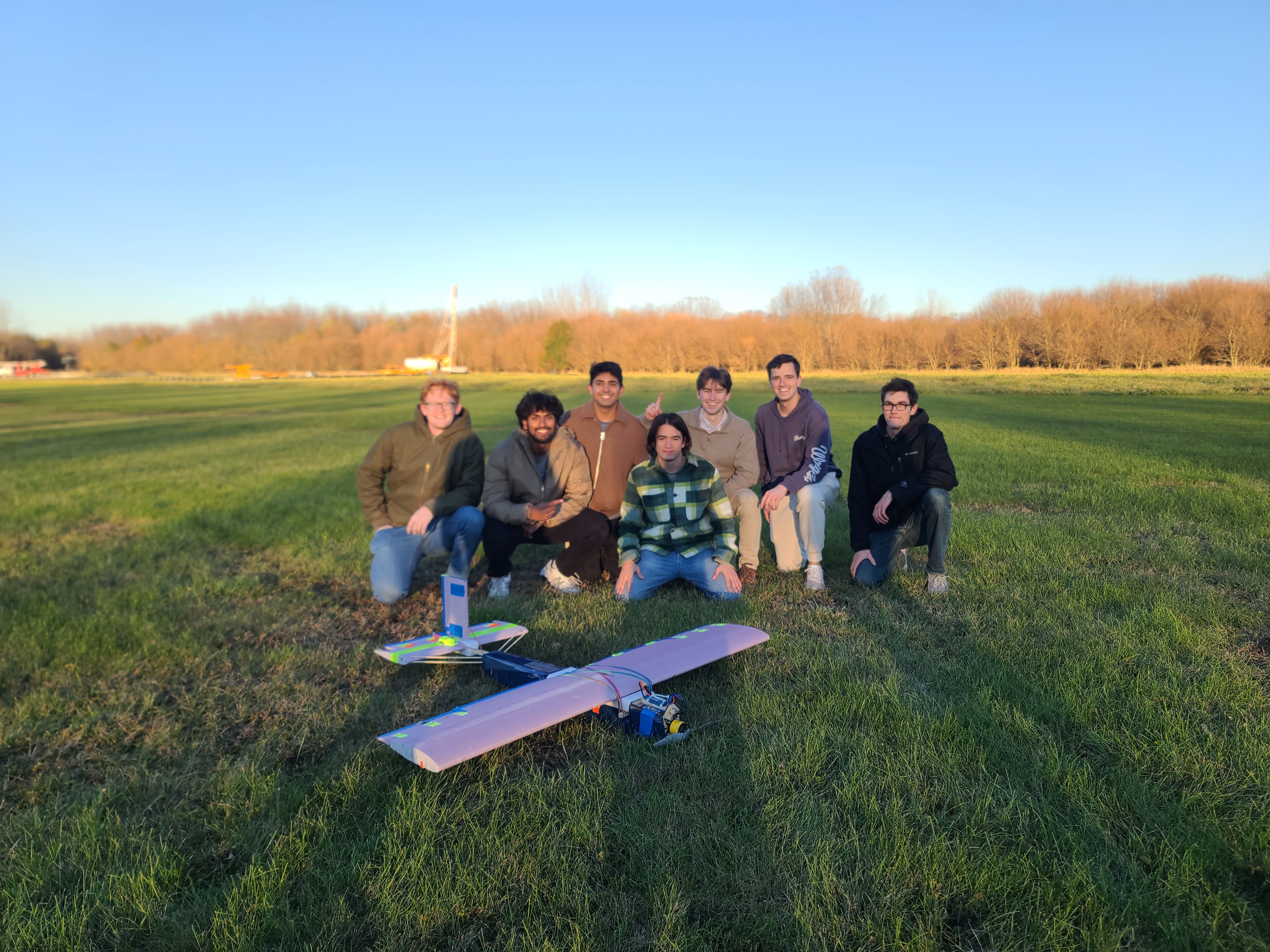

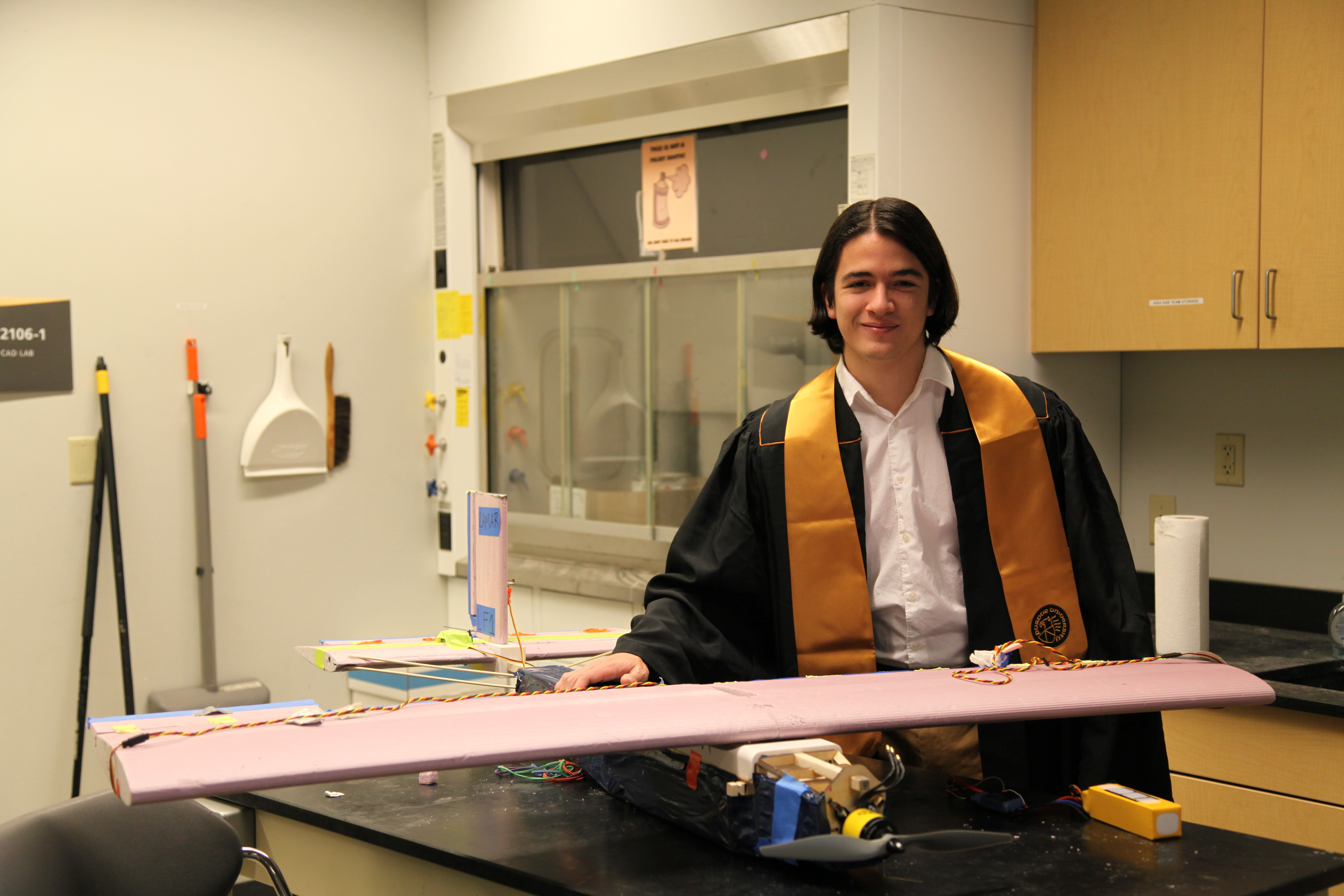

Designed for speed and efficiency. Our senior design team built a fixed-wing aircraft to maximize payload-to-time ratio over a 3-lap circuit. As the propulsion lead, I optimized the powertrain for performance and endurance. The aircraft featured a high-wing monoprop configuration, belly landing, and hand launch capability. It achieved the 2nd best score and won best overall team performance in the competition.

Technical Details

- Role: Propulsion Lead

- Configuration: High-wing, monoprop, belly land, hand launch

- Control Surfaces: Ailerons, vertical stabilizer, horizontal stabilizer

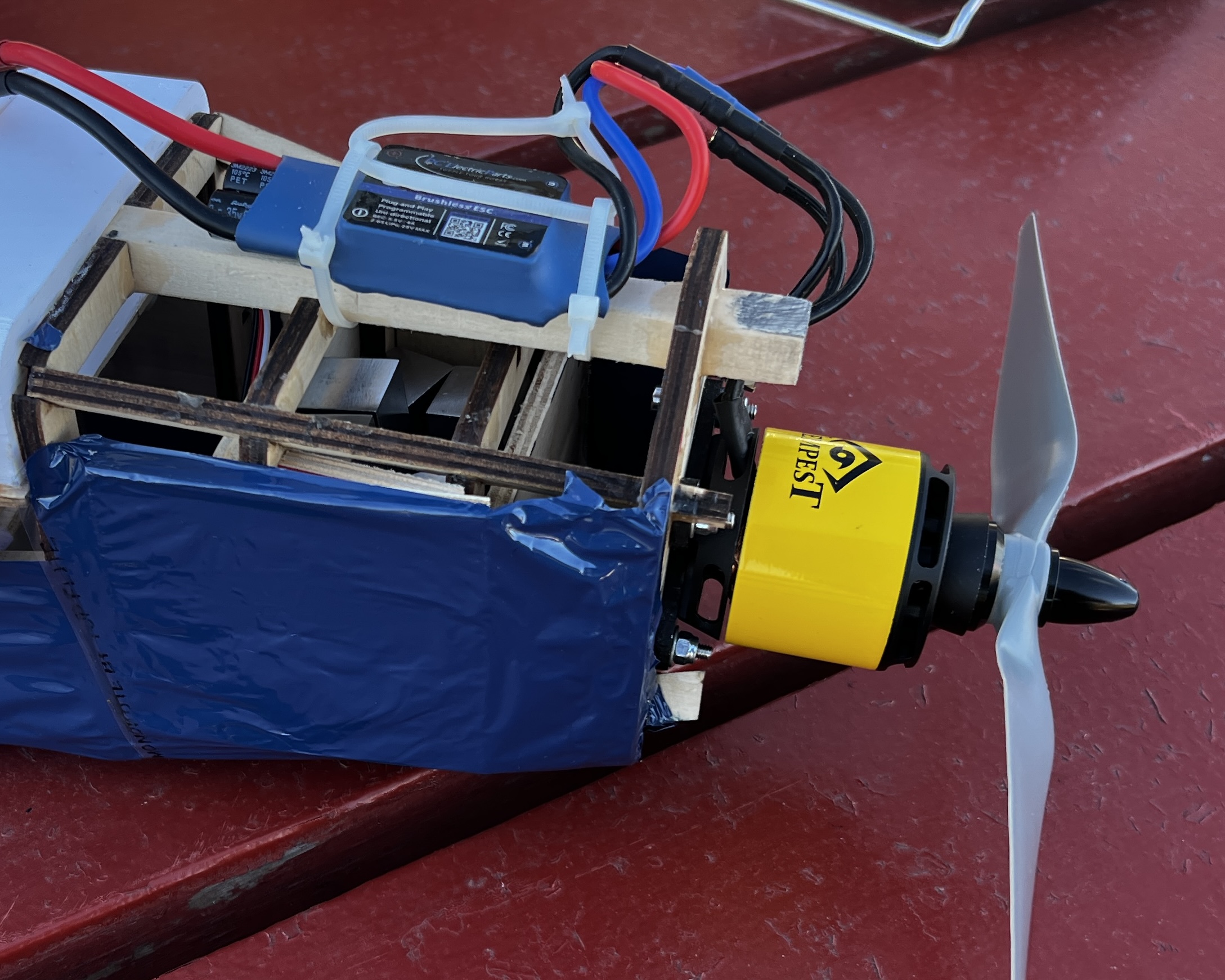

- Powertrain: 540KV motor, 80A ESC, 6S 3300 mAh LiPo battery

- Propeller: 13in plastic

- Weight: Empty - 5.69 lbs, Gross - 8.66 lbs

- Payload: 14 cubes (2.18 oz each)

- Flight Performance: Flight time - 90s, Max RPM - 10,000

- Aerodynamic Metrics: Max L/D - 12.5, CL_max - 1.4

- Thrust-to-Weight: 0.85

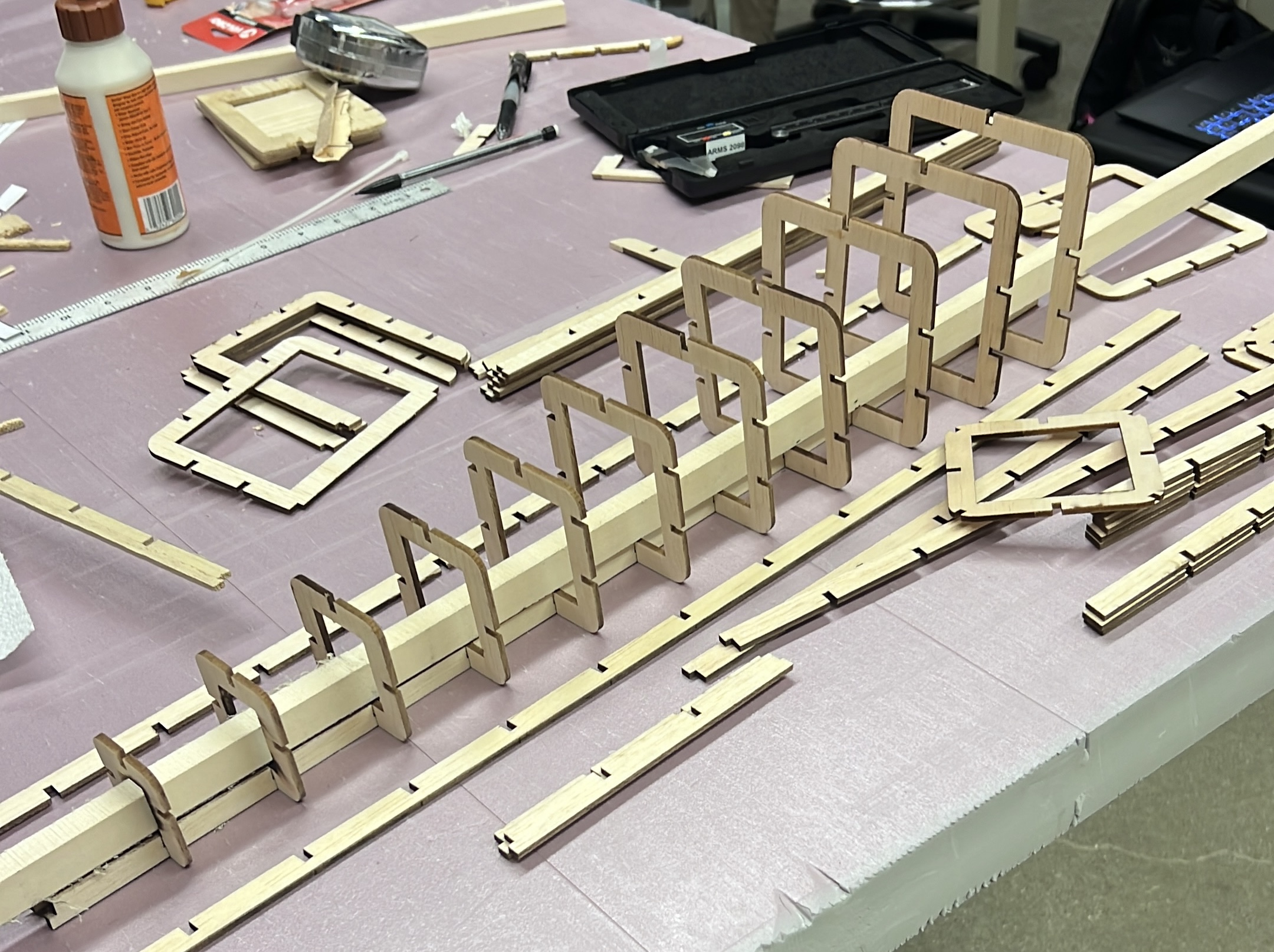

- Materials: Balsa fuselage, foam wing with wood spar

- Cost: $385

Development Process

- Design Optimization: Used XFLR for aerodynamic analysis and control stability simulations.

- Powertrain Selection: Chose motor, ESC, battery, and propeller to maximize thrust and efficiency.

- Structural Design: Constructed fuselage from balsa, reinforced wing with a wood spar.

- Flight Testing: Conducted two test flights to refine performance.

Results

- Competition Recognition - Won best overall team performance.

- Top Performance - Secured the 2nd best score in payload-to-time ratio.

- Efficient Design - Achieved an aerodynamic balance with max L/D of 12.5.